INTRODUCTION:

CAM one of the only mechanisms i have never seen before i actually encountered it in the kinematics textbook in my 4th Semester fascinated me and I promised myself that i would do a project with this mechanism and thus born out of this promise is this project which attempts to fabricate a innovative luggage lifting mechanism using multiple CAM's.

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion or vice-versa.

It is often a part of a rotating wheel (e.g. an eccentric wheel) or shaft (e.g. a cylinder with an irregular shape) that strikes a lever at one or more points on its circular path. The cam can be a simple tooth, as is used to deliver pulses of power to a steam hammer, for example, or an eccentric disc or other shape that produces a smooth reciprocating (back and forth) motion in the follower, which is a lever making contact with the cam

Fig 2 : Working of a CAM

PROJECT SUMMARY

• Cam Mechanism is studied and a suitable model is designed.

• The material to be chosen such that it can carry optimal load, cost is less and strength and fatigue life is more.

• The components are first machined and mechanically tested for fatigue and strength in strength of machinery lab for different components.

• The load that can be carried by the lift is determined.

• The model is done manufactured and tested for application.

• The observed readings are then submitted along with the model.

MATERIALS USED

Fig 3 : Materials Used

TESTING OF MATERIALS

The following tests were done in order to determine the suitable material to be used for the various parts of the cam.

• Izod Impact Test of MS Square rods

• Tensile test for MS rods using UTM

• Tensile test for Aluminium rods using UTM

•Izod Test of the Square rods

• These square rods are used to support the structure of our project.

• We tested the hardness of these rods in different sizes and lengths using Rockwell Hardness test.

• The results are as following:

Sample 1: the hardness in different places are 33, 28, 27 HRC

Sample 2: the harnesses are 33, 32, 35 HRC

Sample 3: The harnesses are 30, 19, 20 HRC

• The lengths of the sample square rods are 75x10 mm

Fig 4 : Square Rod after IZOD test

TENSILE test – Aluminium

TENSILE test – Mild Steel

TESTING OF MATERIALS CONCLUSION

Thus it was concluded that

1. Mild steel was a better choice for making the roller follower as :

It could withstand higher loads

The tensile test showed that it had higher tensile strength

It was cheaper and easier to get in the market

2. The Mild Steel Rods could withstand high impacts without breaking hence it was to be used in the making of the cam rod. A square rod is chosen so that the drilling of the holes is easier. The rods were found to be more ductile and less brittle thus preventing a complete breakdown of the cam at higher loads.

Fig 5 : Tensile Test Specimens

MANUFACTURING PROCEDURE

The manufacturing Process can be divided into the following sections

• Frame

• CAMs

• Roller Followers

• Crank rod

• Wooden blocks

• Assembly

FRAME :

1. The Hollow GI Rectangular tubes were cut as follows :

25 cms-1no

75cms -2nos

50cms-2nos

2. Holes of diameter 13mm were drilled with their centres 40 mm apart on the 25 cm tube and holes of 15 mm diameter were drilled 9cms from one edge of the 75cm tubes.

3. The 75 and 50 cm rods were welded together to form two T – Shaped Structures.

4. The T-Shaped Were then Welded together with the 25 cm rod in between.

Fig 6 : Frame in two different views

CAMs :

1. The GI Hollow Circular Pipe was cut 5 into cylinders of 35 mm height

2. A 6mm hole was drilled 10 mm from one edge of the cylinder

3. This process is was repeated for all cylinders

4. The nut and bolt were checked with the drilled holes

Fig 7 : (top) A Single CAM with a nut and bolt

(right) CAMs with nuts and bolts

Crank Rod :

1. The Solid Rectangular MS rods were into 25 cm, 5cm , 5cm rods

2. Holes of diameter 6mm were 40 mm apart on the 25 cm rod

3. The rods were then welded together as shown in the figure

Fig 8 : Crank Rod

Roller Followers :

1. The Mild steel Circular rods were welded with the bearings in such a way that the centre of the bearings were fixed to the rods while the outer wheel was freely rotating

2. The follower edge was then grinded so that the mild steel rod will not touch the cams

3. The bearings were lubricated for free movement

Fig 9 : Roller Followers

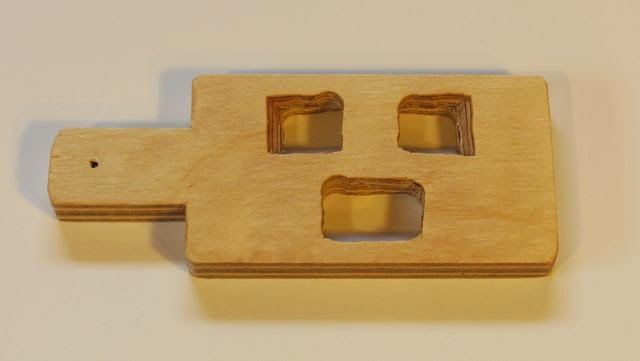

Wooden Blocks :

• The wooden blocks were cut into 30x40x150 mm blocks

• 12 mm holes were drilled in the center of the base with varying depths of 2,3,4,5,6 cms.

• The blocks were then sanded and checked with the follower rods for goodness of fit

Assembly :

• The individual parts made were then assembled and lubricated for free movement

• The working of the cam was then checked

• Any problems encountered were noted and fixed

Problems Faced and Sources of error

• The holes were not of uniform diameter and improper allignment initially which resulted in the jamming of the cam

• Welding without compromising on the alignment of the frame was difficult

• Weld heat would melt the rods when too much current was given to the weld in arc welding

• The bearing expanded on fast welding which stopped its rotary motion

• The cam pipes got deformed when held in the bench wise for cutting if held too tight.

• The cam pipes cut were not cut perfectly cylindrical if the bench wise was too loose.

• The follower rods were not of uniform orientation during the rotation of the cam mechanism.

Scope for improvement

• The crank rod can be replaced with a cylindrical rod to reduce friction and easier movement. (if we can drill holes in cylindrical rods)

• Grooving on the cam will help the roller follower maintain its path.

• A motor attached to the crank rod can help in applications in real life as perhaps a luggage carrier or an alternative for conveyor belt mechanism.

CONCLUSION

CAM mechanism was studied and was applied to make a luggage carrier model. The parts were tested for the required strength based on which a suitable material was chosen. The components were machined and welded to form the parts of the CAM model. Welding, machining concepts were studied and used accordingly. The CAM was then assembled and its working was tested and studied. Real time application of model was also researched.