1. INTRODUCTION

Air engine is a type of motor which does mechanical work by expanding compressed air. Pneumatic motors

generally convert the compressed air to mechanical work through either linear

or rotary motion. It has existed in many forms over the past two centuries,

ranging in size from hand held turbines to engines of up to several hundred

horsepower. Some types rely on pistons and cylinders, others use turbines. Many

compressed air engines improve their performance by heating the incoming air,

or the engine itself. Pneumatic motors have found widespread success in the hand-held

tool industry and continual attempts are being made to expand their

use to the transportation industry. However, pneumatic motors must overcome

inefficiencies before being seen as a viable option in the transportation

industry.

2. MATERIAL USED

|

S. No.

|

Item

|

Specifications

|

|

1

|

PLYWOOD

|

2

metre x .60 m x.10 m

|

|

2

|

ROSE

WOOD

|

.60

m x .20 m x .30m

|

|

3

|

FEVICOL

|

200

ml

|

|

4

|

SUPER

GLUE

|

10

ml

|

|

5

|

SCREWS

|

1 INCH-10 Nos

|

|

6

|

Nails

|

I

INCH -1O Nos.

|

3.

FABRICATION PROCESS

1.

CUTTING OF PARTS

Following

Parts are prepared using carpenting BOSCH tools like jig-saw.sander,roter etc:

·

Flywheel • Piston rod

·

Control rod

·

Crankshaft

·

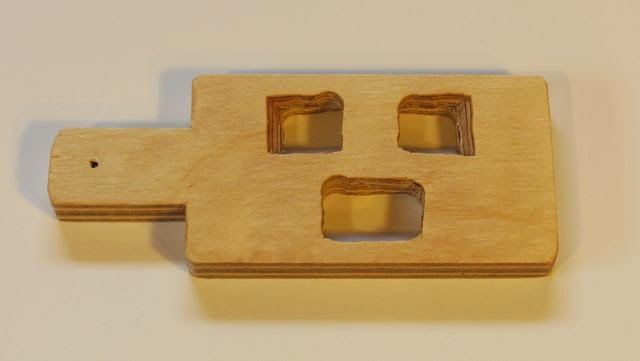

Piston Housing

·

Bearing block

·

Cylinder mount

2.

ASSEMBLY OF PARTS

·

We assembled the piston housing using

wood screw , super-glue and fevicol.

·

The valve slider was connected to

crankshaft such that the control rod moves freely.

·

Fix the bearing block onto the base as

per requirement.

·

Then ,we connect the flywheel to the

crankshaft such that flywheel rotates with the crankshaft.

·

The connecting arm was attached to the

piston such that it moves freely and other arm was connected periphery of the

flywheel such that piston moves connecting arm rotates the flywheel.

·

Piston housing was mounted on the

cylinder mount and cylinder mount was nailed on the base.

·

The bearing block was closed such that

crankshaft was placed between two bearing block and crankshaft axis passing

through the holes in the bearing blocks.

can you send me project plan of this model

ReplyDeletefarooq7797@gmail.com

will charge 400 ,ok ?

DeleteI will pay i need plain.

DeleteI will pay i need plain.

DeleteContact me mutthairkhan@gmail.com

DeleteContact me mutthairkhan@gmail.com

DeleteI want full report contact in gnanasekaran.gm@gmail.com

ReplyDeleteI want full plane complete dimensons reply me earl as possible

ReplyDelete