INTRODUCTION

Hydraulic machines had continued to fascinate me in the third semester and when i was given the oppurtunity to do a design project i pounced at the opportunity to do a hydraulic press

Background:

A

hydraulic press is a machine

using a hydraulic cylinder to

generate a compressive force. It uses the hydraulic equivalent of a mechanical

lever, and was also known as a Bramah

press after the inventor, Joseph Bramah, of England.

Different

types of Hydraulic presses are:

- . Deep Drawing Press- a flexible press used for advanced deep drawing.

- . Blanking Press– a press range for blanking,forming and coining operations, in fully automatic design.

- . Multi-Purpose Press-a versatile press for various forming operations.

- . Large Bed Press – a Press specially designed for forming of large components.

- . Hydroforming Press – forming of tube and sheet parts with the aid of fluid subjected to high pressure.

- . Transfer Press–a compact, modular based press for complete production lines.

Product

The Hydraulic Press is an apparatus

designed, built, and used for forging metal. This press was designed to be

versatile and capable of producing up to 250 ton of force.

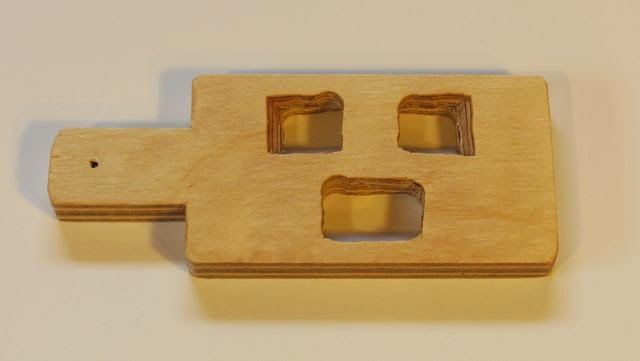

Model

LITERATURE STUDY

Advantages:

The Working Principle:

A hydraulic press is a machine that uses pressurized liquid to create force. These machines are composed of a simple cylinder and piston mechanism. The press consists of a large cylinder, with a large piston, and a small cylinder and a small piston. The large cylinder and the small cylinder are connected to one another by means of a pipe. The two cylinders, and the pipe connecting them, are filled with a liquid. At this point, the function of the hydraulic press depends on Pascal's Principle.Pascal's Principle states that when pressure is added to a liquid at rest, there is an identical increase in pressure at all points. Applying this principle to the hydraulic press means that any force that is added to the piston in the smaller cylinder will be transferred to the piston in the larger cylinder, in a proportionally increased level of force. This allows a hydraulic press to produce a great deal of force from the application of a small amount of force to the small piston.

As air enters the booster cylinder, oil is displaced in the hydraulic cylinder above. The displaced oil enters the ram cylinder and drives the ram down. Pressure is maintained throughout the entire stroke. When the valve is de-energized, the ram retracts to its home position.Advantages:

Advantages

of Hydraulic Press over a mechanical press:-

- Full power stroke

- Built-in overload protection

- Much lower original cost and operating costs

- Larger capacities at lower cost

- More control flexibility

- Greater versatility - A single hydraulic

press can do a wide variety of jobs within its tonnage range. Commonly

seen are deep draws, shell reductions, urethane bulging, forming, blank

and pierce, stake, punch, press fits, straightening, and assembly. They

are also used for powered metal forming, abrasive wheel forming, bonding,

broaching, ball sizing, plastic and rubber compression, and transfer

molding.

- Quiet

- More compact

- Lower tool costs

- Safety - No manufacturer will (or should) claim that

hydraulic presses are safer than mechanical presses. Both types of

machines are designed and built to be safe if the controls and safety

features built in are used properly.

- Less Heat.

Improperly

used, all machines are potentially dangerous. But the factor of control of the

ram movements makes hydraulic presses easy to make safe. Non-tie down,

anti-repeat, dual palm button controls are used. The interlocking of guards, as

well as other safety devices, is relatively easy because of the nature of a

hydraulic press control system.

Isometric view of Hydraulic Press (Fig

B):

Exploded view of Hydraulic Press (Fig

E):

DETAILING AND MANUFACTURING

INFORMATION

The various parts that were

created for making the Hydraulic Press along with their manufacturing

information are as follows.

1.

Base

(Fig 1.1 and Fig 1.2): A base is a structural system

that supports other components of a physical construction. It is a building technique based around vertical

structural members, usually called studs, which provide a stable frame to which

interior and exterior wall coverings are attached. It is made of cast iron.

2.

Piston (Fig

1.3): A piston is a component whose purpose is

to transfer force from ‘pushed fluid’ in the cylinder to the crankshaft via a

piston rod and/or connecting rod ; made of mild steel or cast iron.

3.Ram (Fig1.4 and Fig 1.5):- It is the

component which is used to apply pressure on the die ;usually made of cast iron

or galvanised iron

5.Cylinders (Fig1.7):-It contains the fluid, so is made of a rigid and insulating material like composite material.

7.Nuts(Fig1.9):- A nut is a type of fastener with a threaded

hole. Nuts are graded with strength ratings compatible with their respective

bolts; for example, an ISO property class 10 nut will be able to support the

bolt proof strength load of an ISO property class 10.9 bolt without stripping.

Likewise, an SAE class 5 nut can support the proof load of an SAE class 5 bolt,

and so on. Nuts are made of mild steel.

9.Pressure

Gauge(Fig2.0):- It is used to measure pressure of the fluid. It is an external

device.

METHODOLOGY

The Hydraulic Press was

modelled using the drafting and modelling software ‘SolidWorks 2012 x64

edition’.

The whole project

involves phases namely part modelling of the components of ‘Hydraulic Press’

followed by assembling them. Finally, 2-D drafting of the components was done.

Various tools included

in the software which were used while modelling the components were ‘Revolve

Base’, ‘Extrude Base’, ’Extrude Cut’, ’Circular Pattern’, ‘Hole Wizard’,

Angular Extrudes were

made using tools like ‘Reference Geometry’

Basic motion analysis

was done in solid works and animation wizard in Inventor Autodesk.

Conclusion

We were able to

understand the structural and functional details of a C-250 similar Hydraulic

Press and express it successfully as a SolidWorks project (along with motion

analysis).In this process, the manufacturing details of various parts have also

been seen.

Thus, this project has helped to

enhance our hands-on interface with the software.